作者:文思特咨询师杜建生

读者朋友,您好。

上一篇我们分享了ASQ推出的《质量工具箱第3版(Quality Toolbox 3rd Edition)》中关于汽车供应链常用的“控制计划”的片段,本文继续为您分享:

片段2:数字时代的 工业4.0和质量4.0

In the fast-paced world of technology, industries are constantly evolving to meet the demands of the market. One such evolution is the emergence of Industry 4.0, a term that encompasses the integration of digital technologies into manufacturing processes. Quality 4.0, an offshoot of Industry 4.0, focuses on leveraging these technologies to enhance quality control and assurance. This section highlights the concept of Industry 4.0, its impact on quality management and the role of quality professionals, and quality tools that can help professionals in this digital era.

在快节奏的科技世界中,各行各业都在不断发展以满足市场需求。其中之一就是工业4.0的出现,它是一个将数字技术融入制造流程的术语。质量4.0是工业4.0的一个分支,其重点是利用这些技术加强质量控制和保证。本节重点介绍工业4.0的概念、其对质量管理的影响和质量专业人员的作用,以及可在这个数字化时代帮助专业人员的质量工具。

Industry 4.0

工业4.0

Industry 4.0, also known as the “Fourth Industrial Revolution,” represents a paradigm shift in manufacturing and production. It involves the integration of various advanced technologies such as the Internet of Things (IoT), artificial intelligence (AI), big data analytics, cloud computing, and robotics. These technologies enable automation, real-time data analysis, and connectivity between machines, products, and humans. The primary goal of Industry 4.0 is to create smart factories that are highly efficient, flexible, and capable of autonomous decision-making.

工业4.0,又称“第四次工业革命”,代表着制造和生产模式的转变。它涉及各种先进技术的整合,如物联网(IoT)、人工智能(AI)、大数据分析、云计算和机器人技术。这些技术实现了自动化、实时数据分析以及机器、产品和人类之间的连接。工业 4.0 的主要目标是创建高效、灵活、能够自主决策的智能工厂。

Quality 4.0

质量4.0

Quality 4.0 builds upon the foundation of Industry 4.0 by incorporating quality management principles and practices into the digital transformation of manufacturing. It aims to leverage digital technologies to improve quality control and assurance processes, enhance product traceability, and enable predictive maintenance. Quality 4.0 emphasizes the use of real-time data analytics, machine learning, and advanced analytics to detect and prevent defects, reduce variability, and optimize production processes. By embracing Quality 4.0, organizations can achieve higher levels of product quality, customer satisfaction, and operational efficiency.

质量4.0建立在工业4.0的基础之上,将质量管理原则和实践融入到制造业的数字化转型中。它旨在利用数字技术改进质量控制和保证流程,提高产品可追溯性,并实现预测性维护。质量4.0强调使用实时数据分析、机器学习和高级分析来检测和预防缺陷、降低变异和优化生产流程。通过采用质量4.0,企业可以实现更高水平的产品质量、客户满意度和运营效率。

Empowering Quality Professionals

增强质量专业技能

Quality professionals play a crucial role in ensuring that products and services meet the desired standards and quality excellence. In the era of Industry 4.0 and Quality 4.0, their roles become even more critical and transformative as they help organizations thrive in disruption. Here are some key ways in which Industry 4.0 empowers quality professionals.

质量专业人员在确保产品和服务达到预期标准和卓越质量方面发挥着至关重要的作用。在工业4.0和质量4.0时代,他们的作用变得更加关键和具有变革性,因为他们帮助组织在混乱中茁壮成长。以下是工业4.0增强质量专业能力的一些主要方式。

1. Real-time Monitoring and Control

1. 实时监视和控制

Industry 4.0 technologies enable quality professionals to monitor and control production processes in real time. Through connected sensors and IoT devices, they can gather data on various parameters such as temperature, pressure, humidity, and machine performance. These data provide valuable insights into process variations, potential defects, and deviations from quality standards. Quality professionals can take immediate corrective actions, minimizing the risk of quality issues and ensuring consistent product quality.

工业4.0技术使质量专业人员能够实时监控生产流程。通过连接的传感器和物联网设备,他们可以收集温度、压力、湿度和机器性能等各种参数的数据。这些数据为了解流程变差、潜在缺陷和质量标准偏差提供了宝贵的信息。质量专业人员可以立即采取纠正措施,最大限度地降低质量问题的风险,确保产品质量的一致性。

2. Predictive Analytics

2. 预测分析

With the advent of big data analytics and machine learning algorithms, quality professionals can now predict quality issues before they occur. By analyzing historical data and identifying patterns, they can forecast potential defects , equipment failures , and deviations in process parameters. This proactive approach allows for preventive maintenance, early defect detection, and better resource allocation, leading to improved quality outcomes and reduced downtime.

随着大数据分析和机器学习算法的出现,质量专业人员现在可以在质量问题发生之前进行预测。通过分析历史数据和识别模式,他们可以预测潜在的缺陷、设备故障和工艺参数偏差。这种积极主动的方法可以实现预防性维护、早期缺陷检测和更好的资源分配,从而提高质量成果并减少停机时间。

3. Enhanced Product Traceability

3. 增强产品可追溯性

Quality 4.0 enables end-to-end product traceability throughout the supply chain. Through technologies like radio frequency identification (RFID) tags and barcode scanning, quality professionals can track the movement of raw materials, components, and finished products. This traceability ensures accountability, facilitates faster recalls in case of quality issues, and strengthens compliance with regulatory standards. Quality professionals can leverage these data to investigate quality incidents, identify root causes, and implement corrective actions.

质量4.0实现了整个供应链中端到端的产品可追溯性。通过射频识别(RFID)标签和条形码扫描等技术,质量专业人员可以跟踪原材料、部件和成品的移动。这种可追溯性确保了产品责任,有助于在出现质量问题时更快地召回产品,并加强对监管标准的合规性。质量专业人员可以利用这些数据调查质量事故,找出根本原因,并实施纠正措施。

4. Integration of Quality Systems

4. 质量体系整合

Industry 4.0 encourages the integration of quality management systems with other enterprise systems such as enterprise resource planning (ERP) and manufacturing execution systems (MES). This integration allows quality professionals to access real-time data from multiple sources, enabling a holistic view of quality performance across the organization. It facilitates seamless communication, collaboration, and decision-making, leading to streamlined quality processes and faster response times.

工业 4.0 鼓励将质量管理体系与企业资源规划 (ERP) 和制造执行系统 (MES) 等其他企业系统进行整合集成。这种集成使质量专业人员能够访问来自多个来源的实时数据,从而全面了解整个组织的质量绩效。它促进了无缝沟通、协作和决策,从而简化了质量流程,加快了响应速度。

Quality 4.0 Tools

质量4.0工具

While definitive Quality 4.0 tools have yet to be recognized, most industry leaders agree that there is a shortage of appropriate tools to support Quality 4.0 initiatives.

虽然明确的质量4.0工具尚未得到认可,但大多数行业领导者都认为,目前缺乏支持质量 4.0 计划的适当工具。

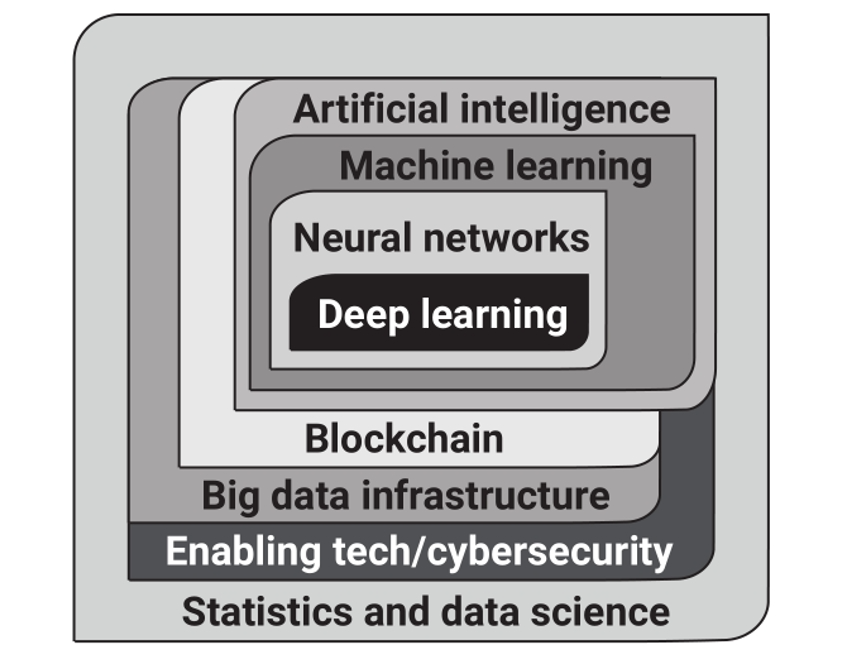

Nicole Radziwill, a pioneer in Quality 4.0 and author of Connected, Intelligent, Automated, identifies an ecosystem of Quality 4.0 tools that can help map business drivers to potential solutions in evaluating business needs (Figure 2.6):

质量4.0 的先驱、《互联、智能、自动化》一书的作者 Nicole Radziwill 指出,质量 4.0 工具的生态系统有助于在评估业务需求时将业务驱动因素与潜在解决方案联系起来(图 2.6):

|

• |

Artificial intelligence 人工智能 |

• |

Deep learning 深层学习算法 |

|

• |

Big data 大数据 |

• |

Enabling technologies 辅助技术 |

|

• |

Blockchain 区块链 |

• |

Data science 数据科学 |

Figure 2.6 Relationships among AI, ML, and infrastructure elements.

图2.6 人工智能、机器学习和基础设施要素之间的关系

(Source: N. M. Radziwill; Connected, Intelligent, Automated (Quality Press, Milwaukee, WI; 2020), p. 53)./《引自质量进展》杂志

Although machine learning (ML) and continuous improvement are analogous, ML adds intelligence and automation to continuous improvement but cannot replace it.

虽然机器学习(ML)和持续改进有相似之处,但ML增加了持续改进的智能化和自动化,而不能取而代之。

The 8D reporting tool covered in Chapter 3 is one such tool. While not exclusively a 4.0 tool, the 8D methodology is a potent problem-solving and communication instrument, particularly in customer complaint scenarios.

第3章介绍的8D报告工具就是这样一种工具。虽然8D方法不完全是4.0工具,但它是一种有效的问题解决和沟通工具,尤其是在客户投诉的情况下。

————

这本书摘抄内容就到这里吧,如果您想对质量工具箱中148种工具有更多的了解,请向ASQ官网购买该书(英文版)。

感谢阅读!

相关链接: