作者:文思特咨询师杜建生

读者朋友,您好。

春天的脚步已经向我们走来。新春之际,美国质量协会ASQ推出了《质量工具箱第3版(Quality Toolbox 3rd Edition)》。该工具箱中介绍了近148种质量工具以适用于不同行业的质量职能(非质量部门)人员参考使用。

本文就工具书的一些主要变化进行介绍,供您参考。

《质量工具箱》被认为自出版以来最受欢迎的质量读物(2005年第2版以来),第3版进行了全面的修订和更新,以适应当前的情形和挑战。

作者注:本书第2版的中文版由中国标准出版社出版,何桢、施亮星主译,各书店有售。

第3版的一些突出变化是:

— 增加了质量4.0(建议的质量工具)介绍

— 增加了汽车行业普遍使用的工具,如控制计划

— 收录了一些其它工具,如九窗法

— 对个别工具进行了修改,如雷达图、盒形图等

阅读这本书,掌握书的阅读指南(书籍的第1章)非常关键,它能帮您快速找到想要了解的工具(结合10步法工具矩阵)。

1. 我们想用这个工具做什么?

(每一个工具下面,可能会出现以下标识,用于工具分类使用的选择)

2. 我们的质量改进进程进展如何?

3. 我们需要思维发散还是聚焦?

本短文摘抄了其中两个片段供您选读:

片段1:

就汽车供应链常用的“控制计划”工具做介绍。

《AIAG 控制计划 第1版》发布在即,我们拭目以待,之后可以关注并比较两本出版物中的异同点。

同样,读者朋友也可以将IATF 16949 8.5.1.1条款及附录A对“控制计划”的要求与SAE(AS13004 PFMEA and Control Plans)中对“控制计划”的要求进行对比。目的是让“控制计划”成为一份“真”的“有作用”文件。

片段2:

简要介绍数字时代的工业4.0和质量4.0

以下是分享的部分:

Also called: process control plan

又名:工序控制计划

Description

描述

A control plan is a document that describes how the desired quality output of a process will be maintained. For each critical quality characteristic, the plan states specifications, actions to measure and monitor them, and actions to take if the characteristic is outside limits.

控制计划是一份描述如何保持工序预期质量输出的文件。对于每个关键质量特性,计划都会明示规范、测量和监视措施,以及特性超限时应当采取的措施。

When to Use

何时应用

• When a part or process is under development, to control key measurements, materials, and performance of the prototype or pre-launch product, or …

• 当零件或工序处于开发时,对原型样件或试生产产品的关键测量、材料和性能进行控制,或...

• After improving a process, to plan how to maintain the gains, and then …

• 过程改进后,要计划如何保持收益,然后...

• Throughout the life of the process, to monitor and control variation, especially…

• 过程整个生命周期,以监视和控制变差,特别是...

• When training people to operate the process, and …

• 培训人员以运行过程,且…

• When process measures are outside limits, to know how to react

• 当测量过程发生超限时,要知道如何应对

Procedure

程序

1. Identify process steps, typically using a flowchart.

1. 确定工序步骤,通常使用流程图。

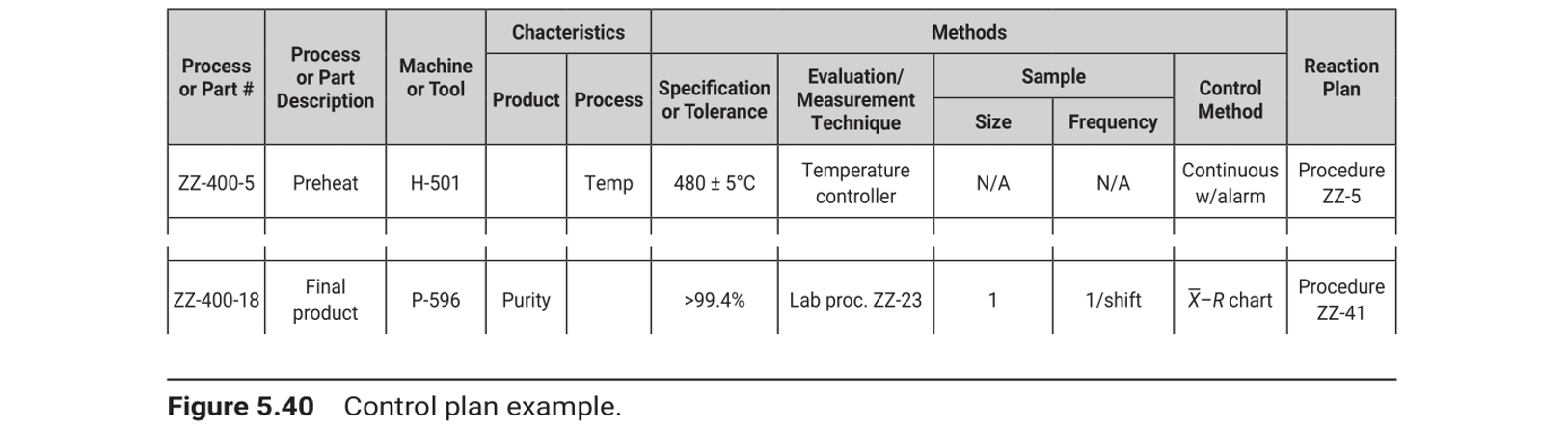

2. Fill in identifying information in the top section of a form like Figure 5.40.

2. 在类似图5.40所示的表格表头填写标识信息。

3. Work on one process step at a time. Identify the process step (or part number, for an assembly), description, and machine or tool used. List them in the first columns.

3. 一次只处理一个工艺步骤。确定工序步骤(或零件号,用于装配)、描述以及使用的机器或工具。将它们列在第一栏中。

4. Characteristics: Identify product and process characteristics that need to be controlled at that process step. Then do steps 5 and 6 for just one characteristic at a time.

4. 特性:确定该工序步骤中需要控制的产品和过程特性。然后,每次只针对一个特性执行步骤5 和6。

5. Methods: Identify the methods to be used to monitor the characteristic. List the specification, measurement or evaluation technique, sample size, sampling frequency, and the control method or chart used.

5. 方法:确定用于监视特性的方法。列出规范、测量或评估技术、样本量、抽样频率以及使用的控制方法或图表。

6. Reaction plan: Define what to do if the characteristic is outside the limits.

6. 反应计划:特性超限时确定做什么。

7. Repeat steps 5 and 6 for each characteristic. Then repeat steps 3 to 7 for each process step.

7. 针对每个特性重复进行步骤5和6。然后对每个工序步骤重复进行步骤3至7。

Example

示例

Figure 5.40 shows two rows from ZZ-400’s control plan, established after the purity team had reached their goals. They had identified preheat temperature as one of the critical characteristics affecting final product quality. It is continually monitored by an automatic temperature controller, which sounds an alarm if the temperature varies from its setting. If that happens, operators follow Procedure ZZ-5. Product purity, a key characteristic of final product quality, is monitored by an X and R chart, using samples taken once per shift. If the process becomes out of control, operators follow Procedure ZZ-41.

图5.40显示了ZZ-400控制计划中的两行,这是在纯度团队达到目标后制定的。他们确定预热温度是影响最终产品质量的关键特性之一。预热温度由自动温度控制器持续监控,如果温度偏离设定值,控制器就会发出警报。如果出现这种情况,操作员就会按照 ZZ-5 步骤进行操作。产品纯度是完成品质量的一个关键特性,通过X和R(均值极差)图进行监控,每班取样一次。如果过程失控,操作员将按照程序ZZ-41进行操作。

图5.40 控制计划示例

Considerations

注意事项

• Control plans help a team think about and formalize how to monitor and control critical variables that affect variation and, therefore, determine whether customer requirements can be met. In Six Sigma, control plans are developed during the C (control) phase of DMAIC to monitor critical-to-quality (CTQ) characteristics, also called the critical Xs and Ys of the product and process.

• 控制计划可以帮助团队思考如何监控影响变差的关键变量,从而确定能否满足客户要求。在六西格玛中,控制计划是在DMAIC 的C(控制)阶段制定的,用于监控关键质量(CTQ)特性,也称为产品和过程的关键 X 和 Y。

• If your organization or customer requires control plans, there will be a standard template. If not, choose or develop a format based on your organization’s needs.

• 如果您的组织或客户需要控制计划,则会有一个标准模板。如果没有,请根据您组织的需求选择或开发一种格式。

• The control plan may be for a part or a process. If you are addressing a family of parts produced in one process, do a control plan for the process.

• 控制计划可以是针对零件或过程的。如果是针对一个过程中生产的一系列零件(族),则应针对该过程制定控制计划。

• Information for the control plan can come from many sources, such as the PFMEA or DFMEA, process flow diagram, part or assembly drawings, design reviews, cause-and-effect diagrams, other root cause analysis tools, statistical studies, and team knowledge.

• 控制计划的信息有很多来源,如PFMEA或DFMEA、工艺流程图、零件或装配图、设计评审、因果图、其他根本原因分析工具、统计研究和团队知识等。

• Identifying information at the top of the control plan should include part or process name and number, revision and original document dates, and contact information for the person responsible for the plan, preferably the process owner.

• 控制计划顶部的标识信息应包括零件或过程名称和编号、修订和初始文件日期,以及计划负责人(最好是过程所有者)的联系信息。

Characteristics

特性

• Product characteristics can be measured or identified on the product itself.

Process characteristics are aspects of the process that affect the quality of what it produces. They are likely to be closer to the root cause of problems.

• 产品特性可以对产品自身进行测量或识别。过程特性是指影响生产质量的过程的各个方面。它们可能更贴近问题的根本原因。

• Some plans include a column for special characteristics. These are characteristics that need special attention due to their impact on form, fit, function, or safety. Some control plans have a column to check to identify CTQ characteristics.

• 有些计划包括一个特殊特征栏。这些特性因其对形状、装配、功能或安全的影响而需要特别注意。有些控制计划有一栏用于检查,以确定CTQ特性。

Methods

方法

• The specification may be qualitative or quantitative. A qualitative specification might not have a tolerance.

• 规范可以是定性的,也可以是定量的。定性规范可能没有公差。

• Measurement system analysis should have been done for the measurement system(s) and should be repeated regularly. Results from the study are sometimes listed on the control plan.

• 应当针对测量系统进行测量系统分析,并定期进行再分析。研究结果有时会在控制计划中列出。

• In discrete manufacturing, the sample size is how many pieces are selected. These pieces will form one subgroup for monitoring on an X and R chart.

• 在离散制造中,样本量是指被选定的件数。这些工件将形成一个子组,在 X 和 R(均值极差) 图上进行监控。

• Typical sample frequencies might be first and last parts produced, last parts only, random sampling, or first and last parts plus parts after tool or material changes.

• 典型的抽样频次可能是生产的首件和末件、仅末件、随机抽样,或者首/末件加上工具或材料更换后的零件。

• Sample frequencies for random failures should be based on how often the failures are known to occur.

• 随机故障的抽样频次应当基于已知故障发生的频率。

• Some control plans distinguish between “control methods: prevention” and “control methods: detection.” Prevention methods include work instructions, drawings, and mistake-proofing. Detection methods include statistical process control (SPC), visual inspection, and automated controls.

• 有些控制计划分为“控制方法:预防”和“控制方法:探测”。预防方法包括工作指导书、图纸和防错。探测方法包括统计过程控制 (SPC)、目视检查和自动化控制。

Reaction plan (or corrective action)

反应计划(或纠正措施)

• The reaction plan should describe actions to be taken by the process operator or the immediate supervisor. It should include actions to ensure defective product does not get to the customer, actions to find the source of the problem, and actions to document and report the situation.

• 反应计划应当说明过程操作人员或直接主管应采取的措施。其中应当包括确保缺陷产品不流入客户端的措施、查找问题根源的措施以及记录和报告情况的措施。

• When developing the reaction plan, think about who, what, when, and where.

• 在制定反应计划时,要考虑由谁、做什么、何时、何地。

• If the reaction plan is lengthy, the chart can refer to a separate reaction plan document.

• 如果反应计划较长,图中可引用单独的反应计划文件。

Developing and using the control plan

制定和使用控制计划

• The control plan is usually developed by the team working on process improvement. After the control plan has been developed, train all the process operators, supervisors, and the process owner.

• 控制计划通常由过程改进团队制定。制定控制计划后,对所有过程操作人员、主管和过程所有者进行培训。

• The control plan does not replace work instructions and standard operating procedures for the process operators.

• 控制计划不能取代过程操作人员的工作指导书和标准操作程序。

• The purpose of the control plan is to ensure that improvements made to the process do not degrade over time. Therefore, the control plan must be a document that can be easily understood and used by the process operators. It also must be periodically reviewed and updated.

• 控制计划的目的是确保对过程的改进不会随着时间的推移而退化。因此,控制计划必须是过程操作人员易于理解和使用的文件。控制计划还必须定期评审和更新。

片段2:

简要介绍数字时代的工业4.0和质量4.0,具体内容见续篇。